Outline

There are two proven methods to ensure actuator operation during a power outage:

-

Using a DC motor

-

Using an air motor

Historically, DC motor-type actuators have been widely used for emergency isolation valves in power plants, as well as in water supply and sewerage systems.

Requirements for DC Motors

-

High starting torque characteristics suitable for valve operation.

-

Line-start applicable motors:

– Unlike general-purpose DC motors, these do not require current-limiting resistance at startup or a complex switching circuit.

– This simplifies the overall circuit design.

Specifications of DC Motor

-

Excitation type: Self-excitation / cumulative compound type.

-

Power supply options:

– 100 V, 110 V, 115 V

– 200 V, 230 V, 250 V (optional) -

Size (output based on starting torque):

#2, #5, #7.5, #10, #15, #25, #40, #60, #80, #100, #150, #200 -

Operating time (Short-time rating):

– 20% load (Intermediate load)

• #2 to #25: 15 mins

• #40 to #200: 5 mins

– 40% load (Intermediate load)

• #2 to #25: 7.5 mins

• #40 to #200: 2 mins -

Brake (Optional)

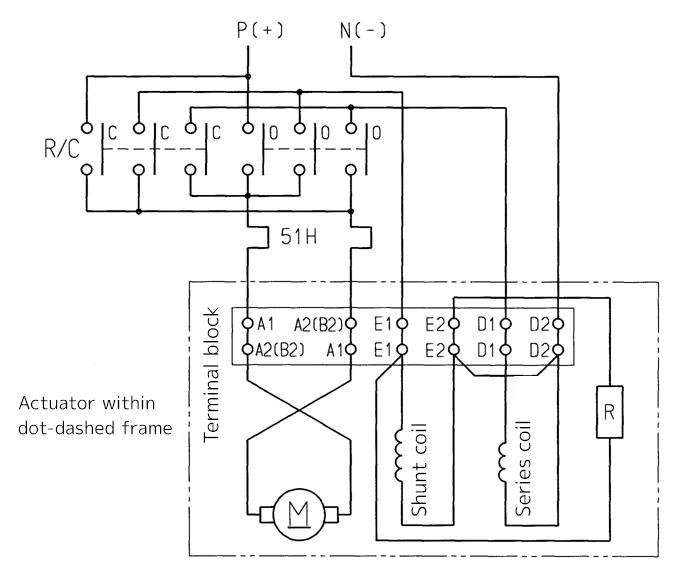

DC motor connection diagram

Notes (Connection Diagram & Symbols)

– R/C: Reversible electromagnetic switch

– 51H: Thermal relay heater

– R: Discharge resistance

Important:

-

External wiring to E2 terminal is prohibited.

-

“R” indicates discharge resistance.

-

For motor size #7.5 and above (with interpole), B2 is used instead of A2 as the terminal marking.

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.